100X Automated Filter Tester

The 100X is perfect for testing N95, KN95, FFP, and P100 respirator masks.

Applications

- Flat sheet filter media

- HEPA / ULPA grade

- Electret media

- Filtering face pieces

- Medical device filters

- PAPR filters

Key Features & Benefits

- 100% Sampling Aerosol Detection System

- Three flow rate options up to 170 lpm

- Best-in-class differential pressure measurement accuracy

- Measure filter efficiency up to 99.9995%

- Patented Aerosol Replenishment System eliminates production downtime

- Automatic, Hybrid & Manual configurations

- Quiet – ideal for QC and R&D labs

Meets Global Industry Standards

- NIOSH 42 CFR Part 84: Respiratory Devices

- ISO 23328: Breathing System Filters for Anesthetic and Respiratory Use

- GB 2626: Respiratory Protective Devices

- JICOSH/JMOL

- GB 19083

- GB/T 32610

- YY 0469

- EN 13274-7:2019 Paraffin Test

- EN 12941/EN 12942

- EN 143/EN 149

- ASTM F3502-21: Barrier Face Covering

- ASTM F2100-23: Medical Face Mask

Delivering Best-in-Class Performance and Low Cost of Ownership

The 100X is a highly accurate, flexible, automated filter tester used to test a wide range of filter media and designed to optimize production yields while delivering the lowest cost of ownership.

Click the video to learn more.

100% Sampling Aerosol Detection System

The 100% Sampling Aerosol Detection System is capable of testing a wide range of HEPA and ULPA filters, up to 99.9995% efficiency. Its innovative design provides a single source of truth, reduces potential sampling errors inherent in legacy designs and with fewer, more robust parts, reduces serviceability costs while increasing equipment uptime.

Best-in-Class Differential Pressure Management Accuracy

The 100X can be configured with your choice of four differential pressure measurement ranges, providing highly accurate, repeatable results that minimize false failures, while increasing both production yields and confidence in the test results.

Automatic, Hybrid & Manual Configurations

The 100X can be configured at time of order to operate three ways:

- The Manual version is ideal for lab use or production lot testing that requires the operator to initiate the test using ergonomic photoelectric actuators. A test fixture for 100 cm2 flat sheet media is included.

- The Automatic version integrates seamlessly with a customer designed, PLC-driven, automated production line and is ideal for 100% in-line non-destructive product testing. The unit is controlled via communication ports and becomes a client device to the automated production line.

- The Hybrid version provides the versatility to operate in Manual mode using the local test fixture or can be switched to Automatic mode using a remote fixture in an automated production environment.

Wide Range of Aerosol Flow Rates

The 100X is capable of air flow rates between 10-170 lpm, providing flexibility to test a wide range of filter types. Integrated flow controller keeps flow rates constant leading to more accurate results. The 100X EN 13274 High Flow option provides aerosol output up to 170 lpm and can be used to test PAPR filters or to optimize production throughput by testing two or more filter cartridges at once in a fully automated production line.

Oil or Salt Aerosol Generation

The 100X is available in either an Oil (DOP, PAO, Paraffin) or Salt (NaCl) aerosol generation models. The patented Aerosol Solution Replenishment System is a separate 2-liter reservoir tank that increases productivity by eliminating the need to shut down production to refill the generator. For salt-based test systems, the replenishment system mitigates aerosol concentration and size / distribution shifts due to dynamic salinity.

Other Features include:

- LCD touch screen user interface

- USB; RS232; PLC-Controls (for Automatic, Hybrid version)

- Compartmentalized design, with easy access for filter replacement and serviceability

| Manual | Automatic | Hybrid | |||||

| # | Description | 100Xs | 100Xp | 100Xs | 100Xp | 100Xs | 100Xp |

| 1 | Canopy Exhaust Connection | 1000665 | |||||

| 2 | Power Cord | 120 V: 6700179 or 240 V: T2E0-0063 | |||||

| 3 | Syringe Assembly | 9300485 | |||||

| 4 | Stylus | 4800263 | |||||

| 5 | Allen Wrench | 3 mm: 4800275 | |||||

| 6 | Ball End Hex Drivers | 4 mm: 4800264 2.5 mm: 4800265 9/64”: 4800266 | |||||

| 7 | Gravimetric Filter Holder | 9300225 | N/A | 9300225 | |||

| 8 | 47mm Gravimetric Filter Holder Assembly | N/A | 9300486 | ||||

| 9 | Gravimetric Holder Opener |

80-00726-001 | N/A | 80-00726-001 | |||

| 10 | Gravimetric Test Media (used with 9300486) |

N/A | T100-0804 | ||||

| 11 | Greenline Penetration Verification Media | 5500175 | |||||

| 12 | Gravimetric Test Media (used with 9300225) |

5500165 | N/A | 5500165 | |||

| 13 | Refill Jug with Cap | 4100172 & 4800152 |

N/A | 4100172 & 4800152 |

N/A | 4100172 & 4800152 |

N/A |

| 14 | Adapter Kit | 0600490 | |||||

| 15 | Reagent Grade NaCl, 500 grams |

8100375 | N/A | 8100375 | N/A | 8100375 | N/A |

| 16 | 1000mL Graduated Cylinder | 4900132 | N/A | 4900132 | N/A | 4900132 | N/A |

| 17 | Brush | 4800267 | N/A | 4800267 | N/A | 4800267 | N/A |

| 18 | Oil Drip Jar | N/A | 20-00777-001 | N/A | 20-00777-001 | N/A | 20-00777-001 |

| 19 | Bracket Strap | N/A | 3000220 | N/A | 3000220 | N/A | 3000220 |

| 20 | Oil Drip Jar Bracket | N/A | 10-00530-001 | N/A | 10-00530-001 | N/A | 10-00530-001 |

| 21 | 5ft Aerosol Line (2) | N/A | 5200192 | 5200155 | 5200192 | 5200155 | |

| 22 | 5ft Pressure Lines | N/A | 20-00754-001 | ||||

| 23 | Pressure Line Jumper Tubes |

N/A | 20-00750-001 | 20-00751-001 | |||

| 24 | Aerosol Line Jumper Tubes |

N/A | 20-00752-001 | 20-00753-001 | |||

| 25 | PLC Port Connection Cable |

N/A | 6700219 | ||||

| 26 | Auto Port Connection Cable |

N/A | 6700222 | ||||

| Not Shown | Aerosol Line Fittings | N/A | 0600503, 0600505 | ||||

| Not Shown | Pressure Line Fittings | N/A | 5100497, 5100785 | ||||

| Not Shown | 1 Gal. DOP Reagent | N/A | T100-0627 | N/A | T100-0627 | N/A | T100-0627 |

| Not Shown | 1 Gal. PAO Reagent | N/A | T000-1075 | N/A | T000-1075 | N/A | T000-1075 |

| Not Shown | MSDS – NaCl | 1800214 | N/A | 1800214 | N/A | 1800214 | N/A |

| Not Shown | MSDS – DOP or PAO | 1800100 1800101 | N/A | 1800100 1800101 | N/A | 1800100 1800101 | N/A |

| Performance & Product Specifications |

|||

| Unit | 100Xp (Oil) | 100Xp (Paraffin) | 100Xs (Salt) |

| Standards | NIOSH 42 CFR Part 84 or Equivalent | EN 13274-7:2019 EN 12941/EN 12942 |

NIOSH 42 CFR Part 84 or Equivalent |

| Reagents | DOP, PAO-4 | Paraffin Oil CAS# 8012-95-1 |

NaCl |

| Available Configurations | Manual, Hybrid and Automatic | ||

| Aerosol Generation | |||

| Particle Size | |||

| Count Median Diameter (CMD) | 0.185 μm ± 0.02 | 0.29 – 0.45 μm | 0.075 μm ± 0.02 |

| Geometric Standard Deviation (GSD) | ≤ 1.6 | 1.6 – 2.2 | ≤ 1.86 |

| Typical Concentration (mg/m3) | 80 – 120 40 – 60 (High Flow) |

15 – 25 15 – 25 (High Flow) |

15 – 25 |

| Flow Rate Options | 10 – 120 lpm (0.18 – 4.2 SCFM) | ||

| 10 – 40 lpm (0.18 – 1.4 SCFM) | |||

| 10 – 170 lpm (0.18 – 6.0 SCFM) | |||

| Aerosol Flow Accuracy | Accurate to ± 0.4% of reading, plus ± 0.2% full scale | ||

| Aerosol Detection |

|||

| Dynamic Range | 0.1 μg/m³ to >200 mg/m³, accurate to ± 1% of reading | ||

| Penetration | 0.0005% | ||

| Efficiency | 99.9995% | ||

| Pressure Management |

|||

| Pressure Range Options | 0-25 mm H²O/0-245Pa; 1:1 TUR | ||

| 0-50 mm H²O/0-490Pa; 2:1 TUR | |||

| 0-100 mm H²O/0-981Pa; >4:1 TUR | |||

| 0-250 mm H²O/0-2452Pa; >4:1 TUR | |||

| Accuracy | ±0.25% of full scale | ||

| Test Fixture | |||

| Standard | Standard Size: ID 11.4 cm (4.5 in.); Allows for flat sheet media testing requiring face velocity of 5.33 cm/s at a flow rate of 32 lpm | ||

| Stroke Height: 14.6 cm (5.75 in.) | |||

| Custom | On Unit: Please inquire | ||

| Off Unit: No size limit | |||

| Communication Ports | |||

| Automatic, Hybrid Models | USB; RS232; Data Connection; PLC-Controls | ||

| Utilities |

|||

| Power | 110 VAC , 5.5A; or 220 VAC, 2.5A (50/60 Hz) | ||

| Compressed Air (Regulator Recommended) |

396 lpm at 6.2 bar ± 0.35 bar (620 KPa ± 35 KPa) or 14 SCFM at 90 psig ± 5.0 psig |

||

| Air Supply Line ID | Minimum 9.5 mm (0.375 in.) | ||

| Dimensions (L x W x H) |

|||

| 100X Main Unit | 71 cm x 69 cm x 89 cm (28 in. x 27 in. x 35 in.) | ||

| Optional Base | 71 cm x 69 cm x 76 cm (27 in. x 28 in. x 30 in.) | ||

| Optional Exhaust | 42.5 cm x 62.8 cm x 40.6 cm (16.75 in. x 24.75 in. x 16 in.) | ||

| Optional Mask Test Adapter | 20 cm x 20 cm x 14 cm (8 in. x 8 in. x 5.5 in.) | ||

| Weight |

|||

| 100X Main Unit | 75 kg (165 lb) | ||

| Optional Base | 38.6 kg (85 lb) | ||

| Optional Local Exhaust | 20 kg (44 lb) | ||

| Optional Mask Test Adapter | 1.6 kg (3.5 lb) | ||

| Compliance | |||

| CE, RoHS, FCC, CSA | |||

PPE Mask Testing

Respirator mask testing is quick and easy with the 100X and optional mask test adapter. Test N95, KN95, FFP, and P100 style respirator masks with confidence. Perform quality control and validation tests to ensure each mask meets industry standards, including NIOSH 42 CFR Part 84, GB 2626, EN 13274-7:2019, and ASTM F3502.

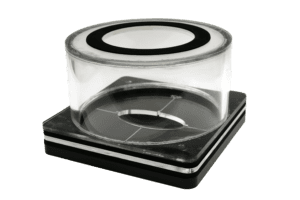

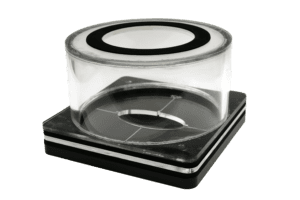

The mask test adapter is an airtight fixture that securely holds a variety of mask styles in place while performing efficiency and resistance tests.

“We recently purchased ATI’s 100X mask test adapter for quality assurance tests of our high-performance filtration masks. Our masks are unique in shape and provide a high level of protection and therefore we needed a mask test adapter that can allow for quick and easy testing. The mask test adapter for the 100X is sturdy, light weight, and is very easy to use. Adhering a mask to the adapter is quite easy using the ATI recommended putty. The design protects the mask under test and best of all the mask test adapter can be cleaned and reused in under five minutes. Accurate results are a must for us and the 100X mask test adapter ensures the results are both accurate and repeatable.”

Sherif Soliman, PhD, MBA

Chief Executive Officer

Matregenix

Ideal for cup and duck bill style masks commonly seen with N95, KN95, FFP, and P100 respirators.

|

|

|

Features & Benefits

- Quick, reliable and easy mask adhesion ensures accurate results

- Accommodates a wide range of N/KN/FFP mask types and sizes

- Sturdy, light weight, acrylic design protects the mask under test

- Affordable, minimal cost per test

- Uses easy to procure, non-toxic adhesive

- Designed exclusively for the 100X

Watch the video to see how easy it is.

Mask Testing in 4 Easy Steps!

1. Secure Mask to SubstrateThe mask is secured to an acrylic substrate using readily available putty. The putty is placed over the edges of the mask to hold it in place. Care is taken to avoid placing putty over the filtration area, as doing so could result in inaccurate test results. |

|

2. Place Substrate with Mask in Mask Test AdapterThe substrate with mask attached are placed on to the mask test adapter base by aligning the two holes in the substrate with the pins on the adapter base. The cover is then placed on top of the mask. |

|

3. Perform a TestPlace the mask test adapter into the test fixture. Follow the on-screen instructions to begin the test. An instantaneous penetration test takes only 10-15 seconds to complete. The mask adapter can also be used for load testing. |

|

4. Clean and ReuseWhen finished remove the mask test adapter from the 100X. The mask test adapter and the substrate can be cleaned and reused for future tests. |

|

| Specifications | |

| Material of Construction | Acrylic |

| Dimensions | 8 L x 8 W x 5.5 H in. (20 L x 20 W x 14 H cm) |

| Weight | 3.5 lb (1.6 kg) |

| Reusable | Yes |

| Items Included with Mask Test Adapter | ||||

| Quantity | Item | Part # | Description | Source |

| 1 | Mask Test Adapter | 20-00840-001 | Acrylic case used to protect respirator masks while testing | ATI |

| 1 | Substrate for Mask | 10-00858-001 | Reusable surface that the mask is attached to | ATI |

| 1 | Wire Frame | 80-0877-001 | Wire frame for mask support | ATI |

| 12 | Putty | 72-00843-001 | Removable, non-toxic material used to adhere the mask to the substrate | ATI or Loctite website |

Accessories:

The 100X can be supplied with an optional local exhaust module to filter all aerosol exhaust when facility exhaust ducting is not available. The local exhaust module is designed with a convenient differential pressure gauge to help determine when to replace the internal HEPA filter. To extend the life of the HEPA filter, turn the 100X off or place it in standby mode when not in use. NOTE: the local exhaust is designed for use in manual mode.

- Reliable local exhaust module, ideal when facility exhaust is not available

- Convenient differential pressure gauge to help determine when to replace the internal HEPA filter

A large base cabinet, convenient for storing manuals and tools is available as an option. The cabinet is equipped with heavy duty locking swivel casters enabling the 100X to be easily moved wherever you need it.

- Large 71 cm L x 69 cm W x 76 cm H (27 in. x 28 in. 30 in.) cabinet convenient for storing manuals and tools

- Large 12.7 cm (5 in.) heavy duty locking swivel casters for portability and stability

The Mask Test Adapter enables testing of N95, KN95, and FFP-style respirator masks with the 100X. The Mask Test Adapter is an airtight fixture that securely holds the mask being tested. The adapter allows the aerosol to enter the adapter and challenge the mask according to industry standards. When the test is complete, the mask can be easily removed, and then the substrate and adapter can be cleaned and prepared for the next mask test.

- Quick, reliable and easy to use

- Sturdy, light weight and reusable

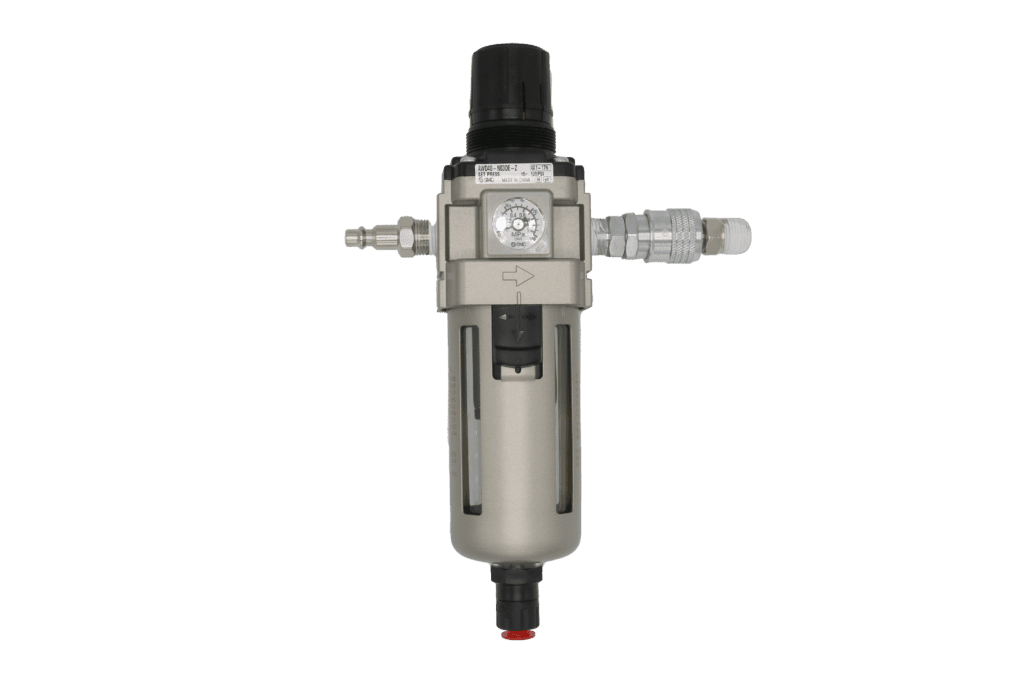

Included for your convenience, the Air Pressure Regulator controls the pressure in the air supply line that is delivered to the 100X. The regulator can be easily adjusted to maintain constant pressure where pressure fluctuations may occur.

- Ensures optimal test results

- Prevents damage

| 100X Accessories | ||

|---|---|---|

| # | Description | Part Number |

| 1 | Local Exhaust Module | 9300224 |

| 2 | Base Storage Cabinet | 9300227 |

| 3 | Mask Test Adapter | 9300503 |

| 4 | Air Pressure Regulator |

9300513

|